INLINE BRIX MONITOR

FOOD & PHARMA

DCM-20

DESIGNED TO:

- Define liquid product interfaces in beverage and dairy products filling lines.

- Achieve and ensure product quality in sugar dissolving, juice blending and jam vessels.

- Correlate membrane filtration efficiency of protein and whey separation in Ultra Filtration systems.

- Optimize steam feed in dairy evaporation processes.

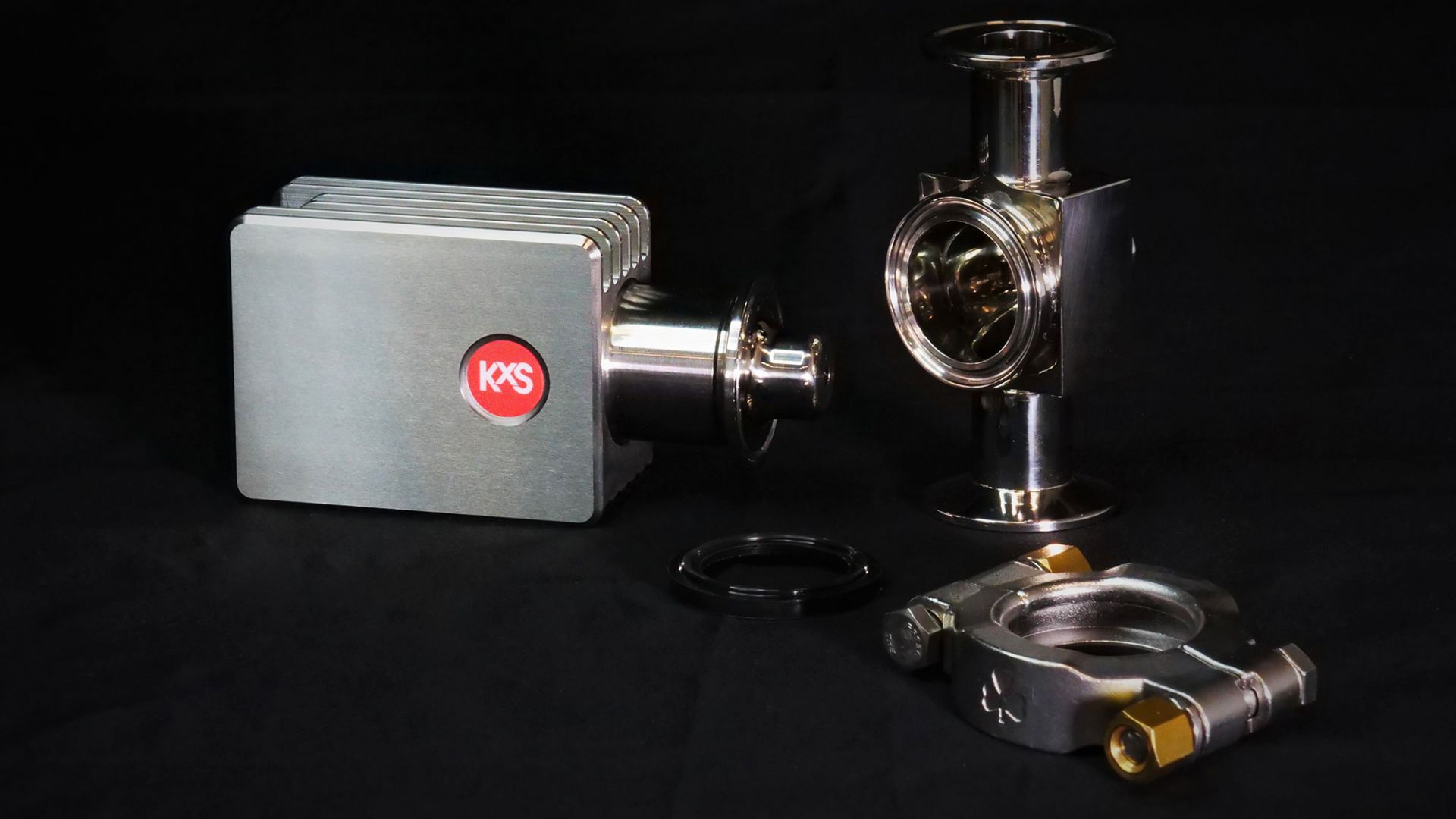

The Inline Brix monitor is installed directly in 1.5" process lines with sanitary tri-clamps. Optional 2.5" sanitary tri-clamp, DN25 APV tank bottom flange and Varinline® connections are presented in the standard product portfolio.

All measurement functions are integrated in the sensor - no transmitter required. Measurement output options are chosen in analog or digital communication protocols. Two cable connection ports are available: Dual analog 4-20mA and Modbus TCP. In the event the nature of the application depends upon a measurement window wash system, the automated wash control is provided through one of the two analog 4-20mA signals. The wash settings are user selectable in the DCM-20 inline Brix monitor's user interface and relay functions integrated in a modular connection unit. External display of different sizes are readily available and connected through the sensor digital port. Computer, tablet or mobile phone with a web browser serves as sensor user interface for accessing diagnostics and settings.

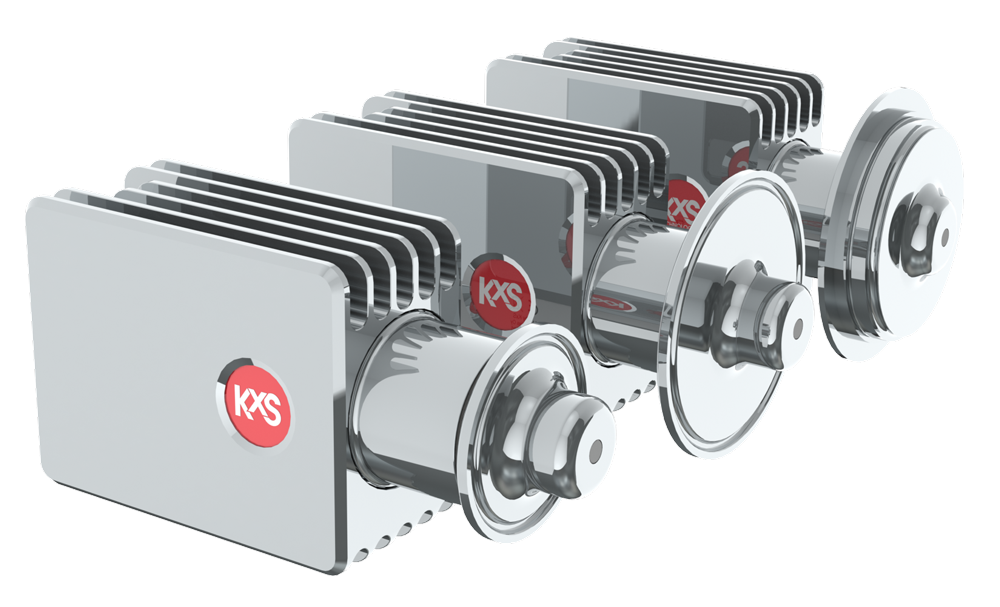

A 1.5” sanitary tri-clamp connection is utilized in 1.5" or larger straight process pipe installations. Single-piece flow cells are similarly installed in straight pipe sections for 1" - 4" process line sizes. The SFC single-piece flow cell is machined from one metal block without weldings, yielding high quality in surface finishing. Pressure rating in the SFC flow cell exceeds 55 bar, 800 psi. Wetted parts are specified with pharma grade stainless steel EN 1.4435 and user selectable gaskets with industry relevant specifications. The unique design with scalable high pressure process connections for membrane separation systems is EHEDG certified and meets 3-A design standards with 3-A symbol authorization.